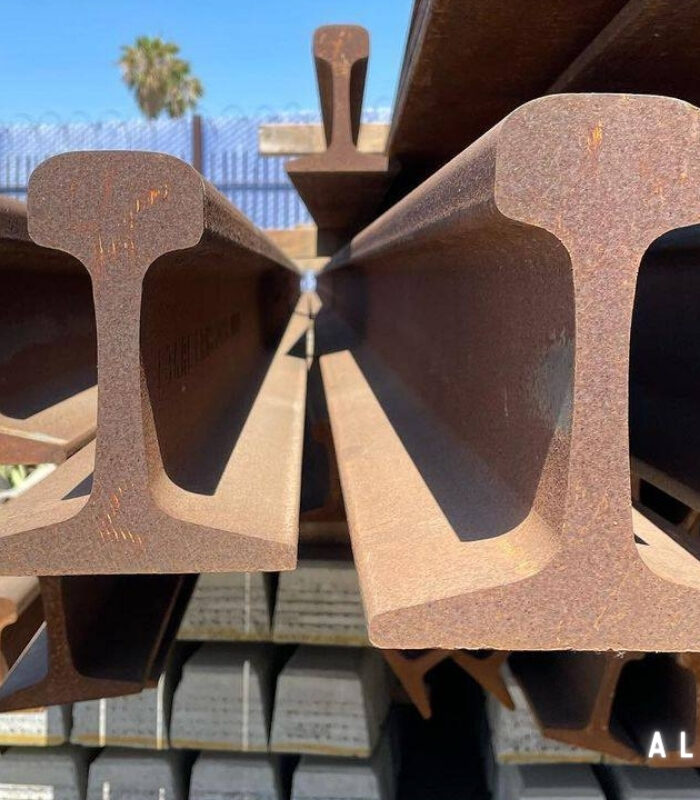

Recycle Process

ALAMAK Recycling Process for Copper Wire:

Collection:

1. Collection Centers: ALAMAK establishes collection centers at various locations to gather copper wire waste from industrial sources, construction sites, and electrical contractors.

2. Sorting: The collected copper wire is sorted based on its thickness, quality, and type (e.g., bare, insulated).

3. Quality Control: A team of experts ensures that only high-quality copper wire suitable for recycling is accepted.

Recycling Process:

1. Shredding: The sorted copper wire is fed into shredding machines that break it down into smaller pieces for further processing.

2. Separation: Through mechanical and electromagnetic separation techniques, the copper wire is separated from other materials, such as insulation or plastic coating.

3. Granulation: The separated copper wire is granulated into small particles to enhance the efficiency of subsequent processing steps.

4. Chemical Stripping: If the copper wire is insulated, it undergoes a chemical stripping process to remove the insulation material.

5. Melting and Purification: The stripped or granulated copper wire is melted in high-temperature furnaces to remove impurities and achieve a high level of purity.

6. Casting: The molten copper is cast into ingots or other desired forms, ready for further processing or sale.

Quality Assurance and Testing:

1. Quality Control Checks: Throughout the recycling process, stringent quality control checks are performed to ensure the purity and quality of the recycled copper.

2. Laboratory Testing: Samples are taken at various stages and tested in the laboratory to verify the copper’s composition and adherence to international standards.

Environmental Considerations:

1. Emission Control: ALAMAK invests in advanced emission control systems to minimize air pollution during the melting and refining processes.

2. Water Management: Proper water treatment and recycling systems are implemented to minimize water usage and prevent contamination.

3. Waste Management: Any residual waste or by-products from the recycling process are appropriately managed and disposed of in compliance with environmental regulations.

Global Distribution:

1. Packaging and Logistics: The recycled copper is securely packaged and labeled for transportation to customers worldwide.

2. Export Channels: ALAMAK leverages its extensive network and partnerships to export recycled copper wire to buyers across the globe.

3. Sustainable Supply Chain: ALAMAK prioritizes sustainable practices throughout the recycling process, contributing to a circular economy and reducing the demand for virgin copper extraction.

By implementing advanced recycling technologies, adhering to stringent quality standards, and focusing on sustainability, ALAMAK ensures the efficient and responsible recycling of copper wire, transforming it into a valuable resource for various industries while minimizing environmental impact..